SHANGHAI HONOR INDUSTRIAL CO.,LTD.

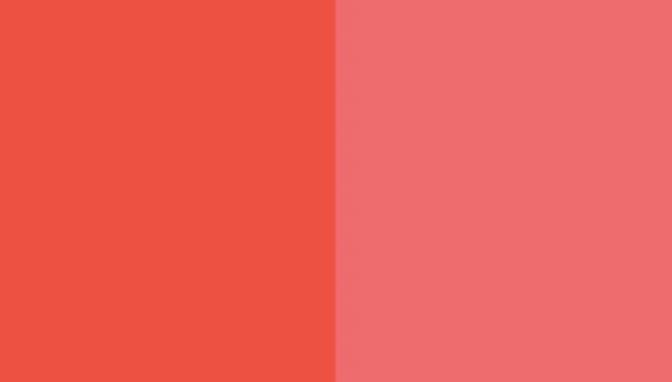

PIGMENT ORANGE 13/ HP ORANGE 3632

PIGMENT ORANGE 13/ HP ORANGE 3632

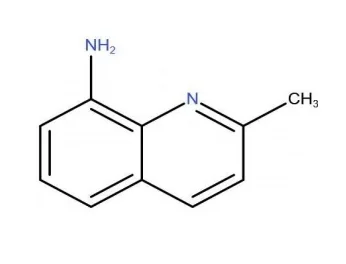

C.I.NO.: PO13

Advantage:

Main Application Recommended: Water based coatings, Water based inks

Description

Product Description – PO13

HP ORANGE 3632 (PIGMENT ORANGE 13) is recommended for water based coating or inks. Its fastness to light is average, and fast to paraffin, butter, and soap. They withstand heat very well and are stable up to 200°C. its lightfastness suits the purpose. Likewise, its resistance to clear lacquer coatings and to sterilization are excellent.

Recommended Application:

Coatings: solvent based coatings, water based coatings, industrial coatings, powder coatings

Plastics: PE, PVC, Rubber/TPV, SBC

Printing inks: offset inks, solvent based inks, water based inks

Technical Data:

| Product Information | ||||

| Chemical Type | Diazo | CAS NO. | 3520-72-7 | |

| C. I. Name | Pigment Orange 13 | EINECS / ELINCS NO. | 222-530-3 | |

| C. I. Constitution No. | 21110 | Chemical Formula | C32H24Cl2N8O2 | |

| Technical Performance | ||||

| Full Shade | Tint | |||

| Weather Resistance | 4 ~ 5 | 3 | Heat Stability °C | 180°C |

| Light Fastness | 6 | 5 | ||

| Physical Properties | ||||

| Physical Form | Powder | Resistance to Acid | 5 | |

| Specific Density (g/cm3): | 1.40 ± 0.1 | Resistance to Alkali | 5 | |

| Specific Surface(㎡/g): | 40 | Migration resistance PVC | 4 | |

| Oil Absorption | 40 | Low warping applications | Suitable | |

| pH Value | 6 ~ 7 | |||

| Volatile Matter | 1% max | |||

| Packaging | ||||

| 25kgs/bag 400kgs/Pallet | ||||

| Storage | Shelf Life | 5 years | ||

| Should be stored in cool, dry and ventilate place. | ||||

| TRANSPORTATION | ||||

| Avoid inversion, sunlight, moisture and crash. Avoid damage the package. | ||||

- Light fastness: Light fastness rating is assessed on 1 to 8 Blue Wool scale where 1 = ‘Poor’ and 8 = ‘Excellent’.

- Heat Stability : Heat stability values given indicate the maximum temperature at which the pigment can be stoved for 10 min. on the full shade and in reductions without undergoing any significant change in shade.

- Oil absorption: The oil absorption is determined on the basis of EN ISO 787-5 and given in g linseed oil per 100 gm. pigment.

- Solvent bleeding: The bleeding in solvents is tested using the powder grades and the visual rating given on 1 to 5 Grey scale

where 1 = ‘Heavy bleeding’ and 5 = ‘No bleeding”

Disclaimer – The information given in this data sheet is based on the present state of our knowledge & is intended as a general description of our products & their possible applications. Due to the multitude of formulations, production & application conditions, all the above mentioned data have to be adjusted to the circumstances of the processor. No liabilities, including those for patent rights, can be derived from this fact for individual cases. It cannot be ruled out that this product contains particles < 0.1 μm. Any user of this product is responsible for determining the suitability of Sudarshan’s products for its particular application & to ensure that any proprietary rights & existing laws & legislation are observed.